Operation Principle

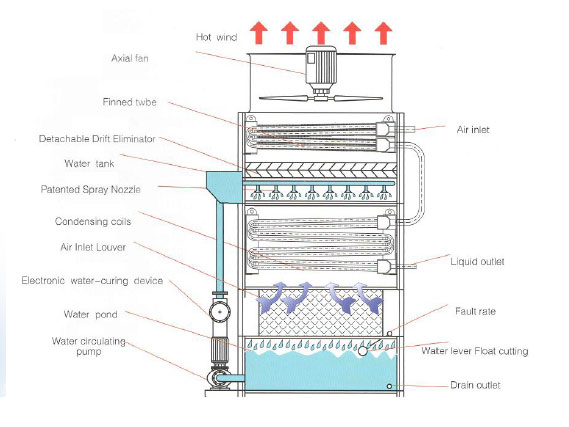

The SPL Hybrid Cooler consists of the Finned air cooled coil(dry), Snake shaped water cooled coil(wet), Spray water device, Drift eliminator(removable) and Water basin. The external part of the cooler is equipment with water circulating pump, Electronic De-scaling Cleaner and Axial Fan(s) on top of the condensing coil.

During operation, the cooling water from the water basin is pumped to the condensing coil evenly forming a thin layer of water film. The induced draft created by the Axial fan(s) draws ambient air from the lower side into the machine and flows over the air cooled coil.

The high temperature steam (work fluid) is pre-cooled by the Finned air cooled coil and then the fluid passes to the condensing coil where major portion of heat is absorbed. The cooled liquid flows out from the lower portion of the condensing coil.

Part of Cooling water evaporates on the coil and drawed out to the atmosphere by the axial fan. The remaining cooling water flows down into the basin for recycling, before which it is cooled by coming in contact with the fresh air drawn from the side louvers.

Main Features

- Patented high technology heat exchange design mechanism.

- High efficiency, energy saving and environment friendly

- Compact and easy to assembly

- Easy and safe to operate

- High quality manufacturing and inspection to ensure long lifetime

Main Application Situations

- The gas cooling between the compressor levels in the process of methanol or ammonia.

- Cooling or condensing of synthesizing gas in producing methanol.

- Cooling or condensing in the process of methanol-rectifying

- Cooling gas for natural gas or coke oven gas conversion process

- Purification process cooling or condensing

- Carbamide waste gas recovery

- Steam condenses for steam turbine